Basics and principles

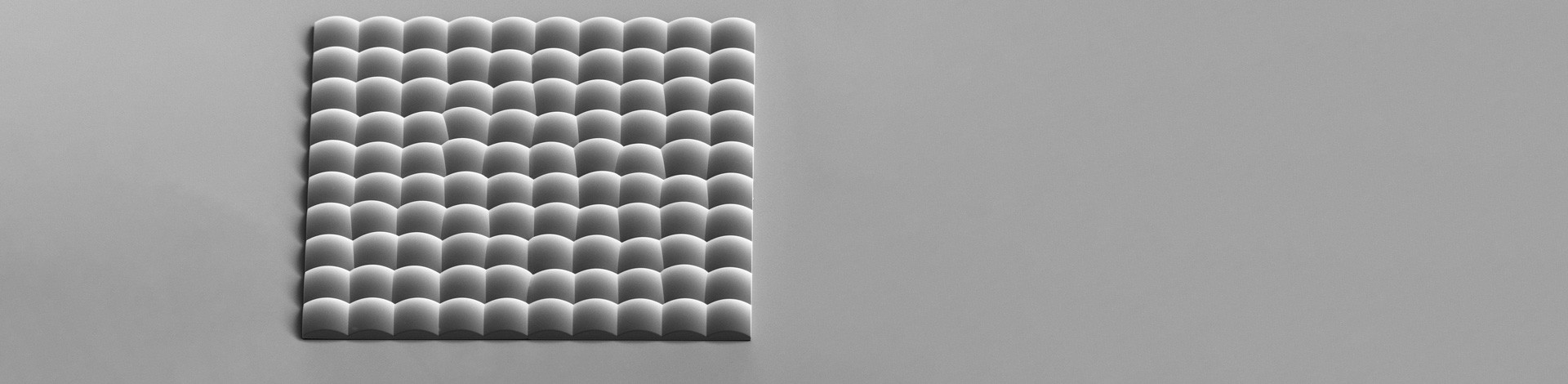

Highest printing performance and

accurate contour control by voxel tuning

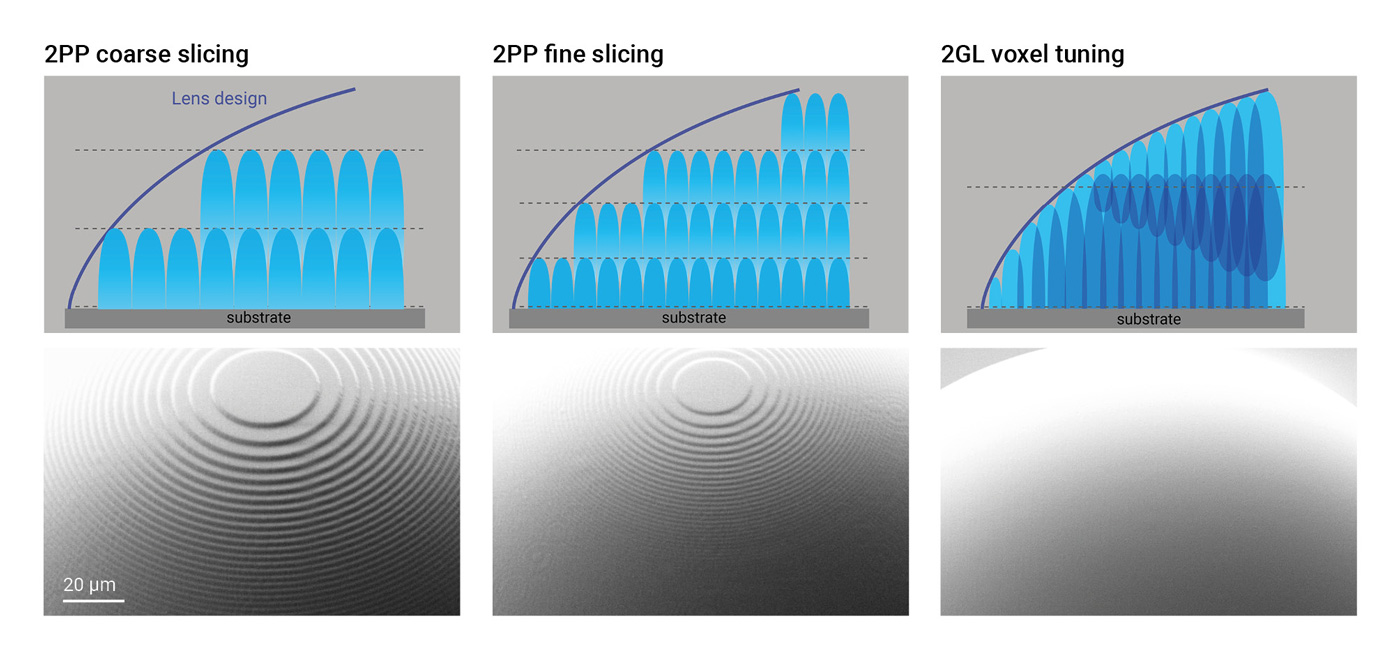

Two-Photon Grayscale Lithography (2GL®) is a new additive manufacturing technology to generate 2.5D topographies. 2GL® is subject to Nanoscribe’s intellectual property. Discrete and accurate steps as well as essentially continuous topographies are printed while scanning only one layer, resulting in drastically reduced print times. 2GL is a new family member of maskless grayscale lithography technologies that uses power-modulated laser light to shape the height profile of micro- and nanostructured functional devices.

Two-Photon Grayscale Lithography (2GL®) is based on Two-Photon Polymerization (2PP). 2GL® is Nanoscribe's proprietary technology that makes use of a dynamic size control over voxels. Modulating the exposure dose while scanning the laser focus across the scanning plane changes the voxel size within the photoresin, resulting in finely controllable size changes of the polymerized voxels. This is the result of synchronizing laser power modulation and high-speed galvo scanning with accurate lateral stage movement. To accomplish this, a grayscale image is converted into a spatial variation of the exposure levels, resulting in different voxel heights being printed in one plane.

2GL printing eliminates stitching seams and tilt-related imperfections

Two-Photon Grayscale Lithography (2GL®) uses high-frequency synchronization of laser beam modulation and high-speed galvo mirrors for single voxel tuning, enabling structures in optical quality. A high-precision positioning unit and self-calibration routines are used to print with excellent accuracy when stitching adjacent print fields together to fabricate large structures. 2GL dynamically adjusts the laser dose at the print field boundaries to compensate for chemically induced shrinkage of the photopolymer and positioning imperfections. With this combination of features, truly seamless structures can be printed over an area of several cm², eliminating all stitching marks.

Even slightly tilted substrates affect print quality, resulting in visible seams when stitching individual print segments or staircases when printing tilted surfaces. The autofocus of Nanoscribe’s printers can be operated on a tight grid of points to automatically measure the substrate tilt. Using 2GL technology combined with automatic tilt compensation, deviations between print blocks and staircase effects can be compensated for. As a result, smooth surfaces without stitching seams or staircase effects are achieved even on tilted substrates.